the drug merchandise has currently been created and packaged. All through an aseptic fill end process, packaging parts along with the drug product or service are sterilized prior to becoming mixed below sterile circumstances.

If these goods are not processed aseptically, it could really encourage contamination. Unfortunately, due to the fact they are immediately injected into sensitive membranes, contaminated products and solutions can seriously impact the tip person.

Improved portability makes sure the sealer is often moved to the method spot where the sterile disconnection is wished-for.

Why is aseptic stability screening done? Security tests gives evidence on how the standard of a drug substance or product or service differs above a offered time and under the impact of environmental elements which includes temperature, humidity, and lightweight. All drug solutions have to undertake balance tests.

For the chance linked to filling line clearance, the impact of not getting suitable line clearance or not staying documented or performed with out QA approval will probably be quite significant. This significant-risk amount is amplified when the detection rating is significant. The full RPN is calculated for being 270 (red).

This web page isn't going to exist in your selected language. Your desire was saved and you'll be notified after a website page could be viewed in the language.

Lack of beneficial merchandise. Contamination of merchandise can render them ineffective and bring about devastating losses for a corporation. In case the contamination will not be caught in advance of dispatch to people, it Filling in Sterile Manufacturing is going to bring about solution recalls. This causes missing have faith in from your prospects.

Liquid bottle filling equipment Engage in a crucial role in ensuring solution versatility and adaptability inside the pharmaceutical industry. These devices are designed to cater to a large spectrum of pharmaceutical merchandise, starting from syrups and oral alternatives to suspensions and ointments.

The welder has just one consumable — solitary-use cutting blades. To ensure clean and sterile welds, chopping blades are discarded immediately after use.

We foresee requires with modifying industry problems to read more stay in time, in inventory, compliant & value aggressive

One of the principal benefits of using liquid bottle filling devices would be the implementation of meticulous good quality Management through the generation process. These machines include automatic devices that monitor Every single stage, substantially reducing the likely for errors and defects.

We foresee requirements with switching market conditions to remain on time, in inventory, compliant & value competitive

Connected SOP really should be revised to cover the use of a checklist to assure the absence of any empty glass bottles inside bottle washing machine for the duration of breaks and at the conclusion of change. The checklist needs to be counter-signed by unit supervisor.

EtherCAT addresses the particular needs confronted in the automation market, when applications require rapidly and specific motion Regulate.

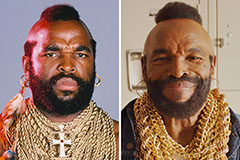

Mr. T Then & Now!

Mr. T Then & Now! Kirk Cameron Then & Now!

Kirk Cameron Then & Now! Michael Bower Then & Now!

Michael Bower Then & Now! Richard "Little Hercules" Sandrak Then & Now!

Richard "Little Hercules" Sandrak Then & Now! Lisa Whelchel Then & Now!

Lisa Whelchel Then & Now!